Coal mining is one of the pillars of energy supply, however, mining activities not only generate valuable mineral resources, but also accompanied by a large amount of exhaust emissions, including high-temperature exhaust gas. These exhaust gases not only waste valuable energy resources, but also create a burden on the environment. However, the innovative application of the exhaust air heat recovery heat pump system is changing this situation, regenerating and utilizing high-temperature exhaust gas, bringing considerable benefits to the coal mining industry.

Coal mine exhaust gas refers to the high-temperature exhaust gas generated during the coal mining process, which is usually discharged into the atmosphere and wastes a large amount of heat energy. At the same time, there is a lack of air in coal mines, which means poor air circulation and a harsh working environment. This not only poses a threat to the health of workers, but also affects the efficiency of mining activities.

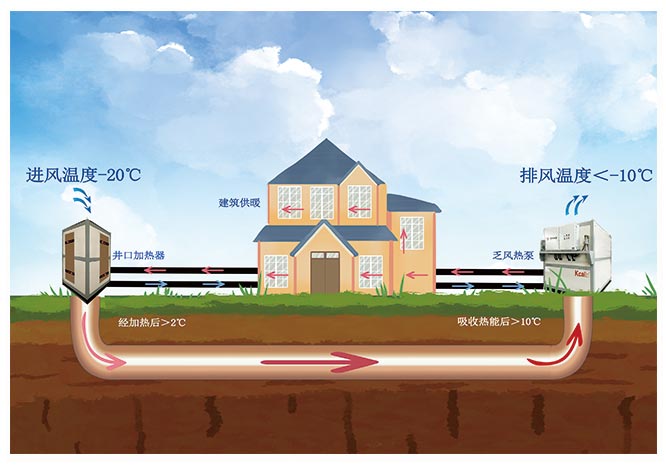

The exhaust air heat recovery heat pump system is an innovative technology aimed at solving this problem. The main principle is heat pump technology, which can capture the heat energy in high-temperature exhaust gas and convert it into usable energy. The following is the basic working principle of a heat pump system:

Exhaust gas capture: The system captures high-temperature exhaust gas through an exhaust gas collection device, which can be achieved through a heat exchanger or exhaust gas pipeline.

Heat pump technology: The captured high-temperature exhaust gas is introduced into the heat pump system, where thermal energy is transferred to the heat transfer medium, usually water or air.

Heat distribution: The system distributes the captured heat energy through pipelines and radiators to various areas in coal mine facilities for heating, hot water supply, or other purposes.

Control system: Heat pump systems are usually equipped with intelligent control systems to monitor temperature and energy demand to ensure efficient operation of the heating system.

This series of work steps converts high-temperature exhaust gas into practical and usable energy, achieving the regeneration and utilization of waste resources.

The exhaust air heat recovery heat pump system has multiple application areas in the coal mining industry, including:

Frost prevention at the wellhead: In deep coal mines, the wellhead area usually faces low temperatures, which may lead to equipment freezing and work interruption. The exhaust air heat recovery heat pump system provides stable thermal energy to prevent freezing equipment, ensuring the continuous operation of the wellhead. This helps improve work efficiency while reducing maintenance and repair costs.

Building heating: Buildings within a coal mine site, such as office buildings, dormitories, and facilities, also require heating. Traditional heating systems typically rely on external energy sources, while exhaust air heat recovery heat pump systems provide a more cost-effective and environmentally friendly heating option for these buildings. By distributing the captured high-temperature heat inside the building, these systems provide workers with a warm working and living environment.

Hot water supply: In addition to heating, heat pump systems can also be used to provide hot water. This is of great significance in the living facilities, restaurants, and bathrooms in coal mines. Through the recovery of exhausted air heat, hot water supply has become a more economical and environmentally friendly solution.

The exhaust heat recovery heat pump system has brought multiple benefits to the mining industry, including:

Energy cost savings: By reducing reliance on external energy, coal mines can reduce heating costs and improve energy efficiency.

Reducing greenhouse gas emissions: Effective energy recovery can help reduce greenhouse gas emissions from coal mines, reduce environmental footprint, and promote sustainable development.

Improving workers' quality of life: Providing heating and hot water improves workers' comfort and quality of life, thereby helping to attract and retain talent.

Resource Sustainability: The waste air heat recovery heat pump technology helps improve resource sustainability, reduce environmental risks in coal mines, and create a more sustainable working environment for the future.

The exhaust heat recovery heat pump system represents an innovative solution that provides multiple advantages for the coal mining industry, from wellhead antifreeze to building heating. It brings multiple benefits to coal mines, including improved energy efficiency, cost savings, reduced greenhouse gas emissions, and improved workers' quality of life. The application of this technology not only helps to improve the sustainability of coal mines, but also helps to meet the growing energy demand while reducing dependence on external energy. In the coal mining industry, the waste air heat recovery heat pump technology has become an important step towards achieving sustainability and innovation.

Comment