The mine ventilation system plays a crucial role in the process of mineral resource extraction. However, traditional ventilation methods often come with significant energy waste. In order to achieve green mining construction and improve the energy utilization efficiency of mines, heat exchanger heat recovery technology has emerged.

The mine ventilation system is mainly responsible for providing fresh air and eliminating harmful gases and dust for underground workers. However, in this process, a large amount of heat is discharged with the exhaust gas, resulting in energy waste. According to statistics, heat loss in mine ventilation systems accounts for over 30% of the total energy consumption of mines. How to reduce this part of energy consumption and improve the energy utilization rate of mines has become an urgent problem for mining enterprises to solve.

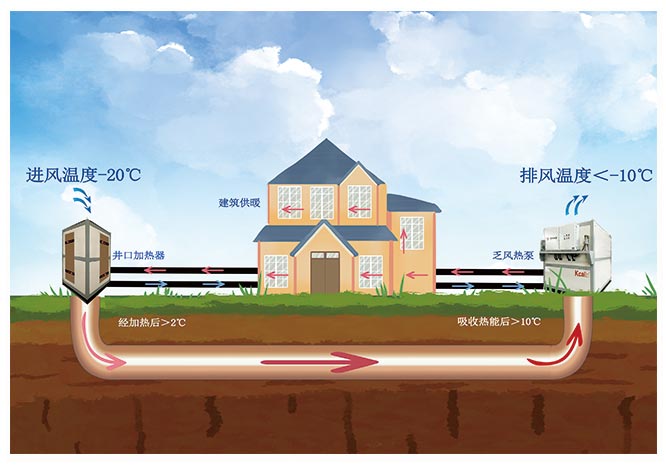

Heat exchanger heat recovery technology is an efficient and environmentally friendly way of energy recovery. The principle is to transfer the heat from the mine exhaust to fresh air through a heat exchanger, achieving the recovery and utilization of heat. Specifically, the heat recovery heat exchanger is mainly composed of two parts: the exhaust side and the supply side. The exhaust side absorbs the heat from the mine exhaust, while the supply side transfers the heat to fresh air, thereby reducing the energy consumption of fresh air preheating.

Application of Heat Exchanger Heat Recovery Technology in Mine Ventilation System

Good energy-saving effect: The use of heat exchanger heat recovery technology can effectively reduce the energy consumption of mine ventilation systems. According to practical application cases, after adopting heat recovery technology in the mine ventilation system, the energy saving rate can reach over 20%, greatly improving the energy utilization rate of the mine.

Improving the working environment underground: Heat exchanger heat recovery technology can not only reduce energy consumption, but also increase the supply air temperature of the mine ventilation system. In cold regions, this helps to improve the working environment underground and increase the work efficiency of operators.

Green and environmentally friendly: By recycling the heat from mine exhaust, heat exchanger heat recovery technology reduces the consumption of energy such as coal, lowers greenhouse gas emissions, and contributes to the construction of green mines.

The application of heat exchanger heat recovery technology in mine ventilation systems has brought good economic and environmental benefits to mining enterprises. With the continuous promotion of green mining construction in China, heat exchanger heat recovery technology will play an increasingly important role. Let's work together to create a green, efficient, and environmentally friendly mine ventilation system!

Comment