With the increasing energy crisis and environmental issues, achieving efficient and environmentally friendly heating has become an urgent need in modern society. The air source screw heat pump unit has gradually become a star product in the heating field due to its high efficiency, energy conservation, environmental protection and reliability.

Air source heat pump is a device that uses the heat energy in the air to heat water or air, and its basic principle is similar to the heating mode of household air conditioning. The main work process is as follows:

Evaporation: An air source heat pump absorbs heat from the air, causing the low-temperature refrigerant to evaporate into gas in the evaporator.

Compression: The compressor compresses low-temperature and low-pressure refrigerant gas into high-temperature and high-pressure gas.

Condensation: High temperature and high pressure refrigerant gases release heat in the condenser, heating water or air while condensing themselves into a liquid.

Expansion: The liquid refrigerant is depressurized and cooled through the expansion valve, and then re enters the evaporator to start a new cycle.

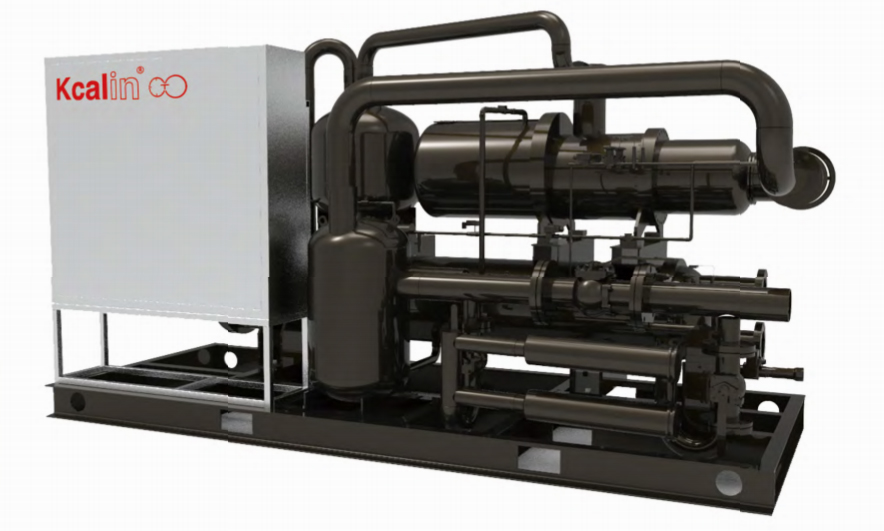

The efficient operation of an air source heat pump relies on its main component - a screw compressor. Screw compressor is a mechanical device that uses screw rotors for compression, and its efficient and stable characteristics have made it widely used in air source heat pump systems.

A screw compressor consists of a pair of screw rotors that mesh with each other. The rotors rotate in the compression chamber, compressing gas from the inlet end to the outlet end. The specific process is as follows:

Inhalation stage: The screw rotor begins to rotate at the intake end, and gas enters the compression chamber through the intake port.

Compression stage: As the screw rotor rotates, the gas is gradually compressed in the compression chamber, and the pressure and temperature continue to rise.

Exhaust stage: High pressure and high temperature gas is discharged from the outlet under the continuous rotation of the screw rotor, completing the compression process.

Screw compressors have the advantages of simple structure, smooth operation, and low noise, making them particularly suitable for application in air source heat pump systems.

The advantages of screw compressors

High efficiency: Screw compressors have high compression efficiency and can provide higher compression power at lower energy consumption, improving the energy efficiency ratio (COP) of the entire heat pump system.

Good stability: The screw compressor operates stably and can adapt to various working conditions, ensuring the reliable operation of the air source heat pump system under different environmental conditions.

Low noise: The operating noise of screw compressors is relatively low, making them suitable for use in residential areas and other places with high noise requirements.

The air source screw heat pump unit converts the heat energy in the air into high-temperature heat through the efficient compression of the screw compressor, which is used for heating or hot water supply. Its operating mechanism mainly includes the following aspects:

Efficient heat exchange: The air source screw heat pump unit adopts an efficient heat exchanger, which can quickly and fully transfer the heat energy in the air to the refrigerant. The design and material of heat exchangers have a significant impact on the performance of heat pump units, and high-quality heat exchangers can improve the energy efficiency ratio of heat pumps.

Intelligent control system: Modern air source screw heat pump units are generally equipped with intelligent control systems, which can automatically adjust the operating status of the compressor and refrigerant flow according to outdoor temperature, indoor demand, and heat pump operation status, optimizing system performance. The intelligent control system not only improves the energy efficiency of the heat pump unit, but also extends the service life of the equipment.

Multi stage compression technology: Air source screw heat pump units usually use multi-stage compression technology to gradually increase the pressure and temperature of the refrigerant in stages, further improving the heating efficiency of the heat pump. This technology is particularly effective in low-temperature environments, ensuring that heat pump units can still operate efficiently in cold weather conditions.

Variable frequency technology: Variable frequency technology is one of the important innovations of air source screw heat pump units. Through frequency conversion adjustment, the speed of the compressor can be dynamically adjusted according to actual needs, achieving efficient operation under partial load, avoiding the energy consumption and equipment wear caused by frequent starting and stopping of traditional heat pump systems.

As an efficient and environmentally friendly heating equipment, the air source screw heat pump unit is gradually becoming the mainstream choice of modern heating systems due to its operating mechanism and diverse application prospects. Through innovative means such as efficient heat exchange, intelligent control, multi-stage compression, and frequency conversion technology, the air source screw heat pump unit has achieved the goal of efficient heating, making important contributions to energy conservation, emission reduction, and environmental protection.

Comment