In cold winter environments, coal mine shafts often face problems of freezing and freezing, posing a serious threat to the safety of mine production. In order to solve this problem, air heating units for winter anti freezing in coal mine shafts have emerged, becoming a reliable choice for safe production in mines.

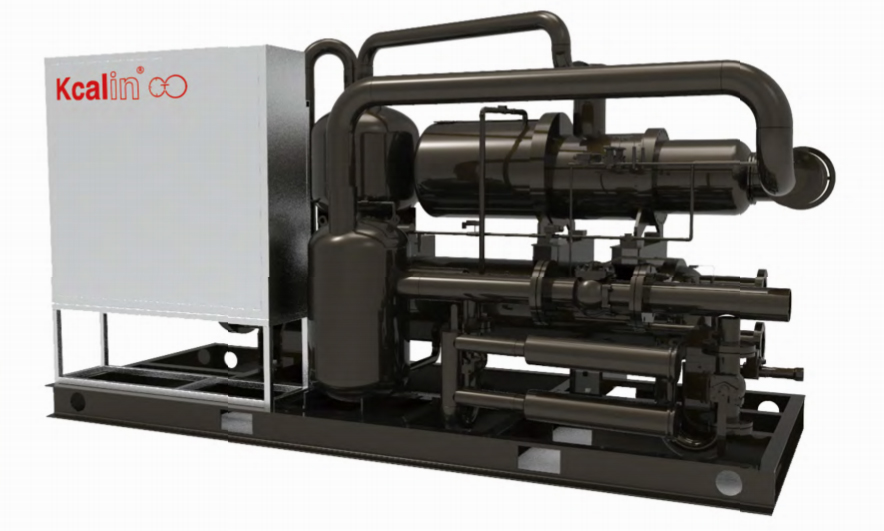

Efficient heating performance: The air heating unit for winter antifreeze in coal mine shafts adopts efficient heat exchange technology, which can quickly heat cold air to a suitable temperature. It uses an efficient heat exchanger to fully exchange heat between the external cold air and the heat source, ensuring a stable increase in the temperature of the air inside the mine and effectively preventing the shaft from freezing and freezing.

Safe and reliable: The air heating unit used for winter anti freezing in coal mine shafts has complete safety protection devices, such as over temperature protection and over pressure protection, to ensure the safe operation of the equipment. At the same time, it has undergone strict design and testing, with stable working performance and reliability, and can adapt to harsh mine environments and complex working conditions.

Environmental protection and energy conservation: The air heating unit used for winter freezing prevention in coal mine shafts uses clean energy for heating, avoiding pollution and emission issues caused by traditional coal-fired heating methods. It can greatly utilize energy, reduce energy consumption and waste, and meet the requirements of environmental protection and emission reduction.

Intelligent control: The intelligent control system equipped with air heating units for winter anti freezing in coal mine shafts can intelligently adjust heating parameters according to actual needs, achieving precise control and energy consumption optimization. Users can monitor and operate remotely to gain real-time understanding of device operation and improve management efficiency.

The air heating unit used for winter freezing prevention in coal mine shafts is a key equipment for safe production in mines. It has advantages such as efficient heating performance, safety and reliability, environmental protection and energy conservation, and intelligent control, which can effectively prevent shaft icing and freezing, ensuring the safe production of the mine.

The benefits of choosing an air heating unit for winter anti freezing in coal mine shafts not only lie in the safety production of the mine, but also include the following aspects:

Improving work efficiency: Freezing the mine shaft can hinder transportation and ventilation, affecting the normal operation of the mine. The use of air heating units for antifreeze heating can effectively eliminate freezing problems and improve the efficiency and production capacity of mines.

Reduce maintenance costs: Shaft freezing not only leads to downtime and production stoppage, but also increases the cost of equipment maintenance and repair. By using air heating units for antifreeze heating, these additional costs can be avoided and the service life of the equipment can be improved.

Enhanced safety: The freezing of the wellbore poses great danger to the working environment of miners. Using an air heating unit for antifreeze heating can effectively prevent wellbore freezing and freezing, ensuring the safety of miners.

Environmental protection and energy conservation: The air heating unit used for winter freezing prevention in coal mine shafts uses clean energy for heating, reducing environmental pollution. At the same time, by optimizing energy utilization and heat exchange technology, we can achieve efficient energy utilization, reduce energy consumption and waste.

When selecting air heating units for winter anti freezing in coal mine shafts, attention should be paid to selecting suppliers with good reputation and high-quality service. Ensure the reliable quality of products and provide comprehensive after-sales service to ensure the stable operation and long-term benefits of equipment.

Comment