Application of air-source heat pump in oil exploitation and transportation. When oil is extracted from the ground, the temperature of crude oil is about 20~40 ℃. The extracted crude oil will be stored in the oil tank and transported by pipeline or tanker to the refinery for refining. Due to the cold climate in some crude oil mining areas, it is necessary to heat and insulate crude oil to facilitate transportation and storage. At present, the commonly used heating and thermal insulation methods for crude oil are coal and gas heating, electric heating and other forms, but there are many disadvantages, such as high energy consumption, unstable heating, which is not conducive to the realization of the national strategic goal of carbon reduction.

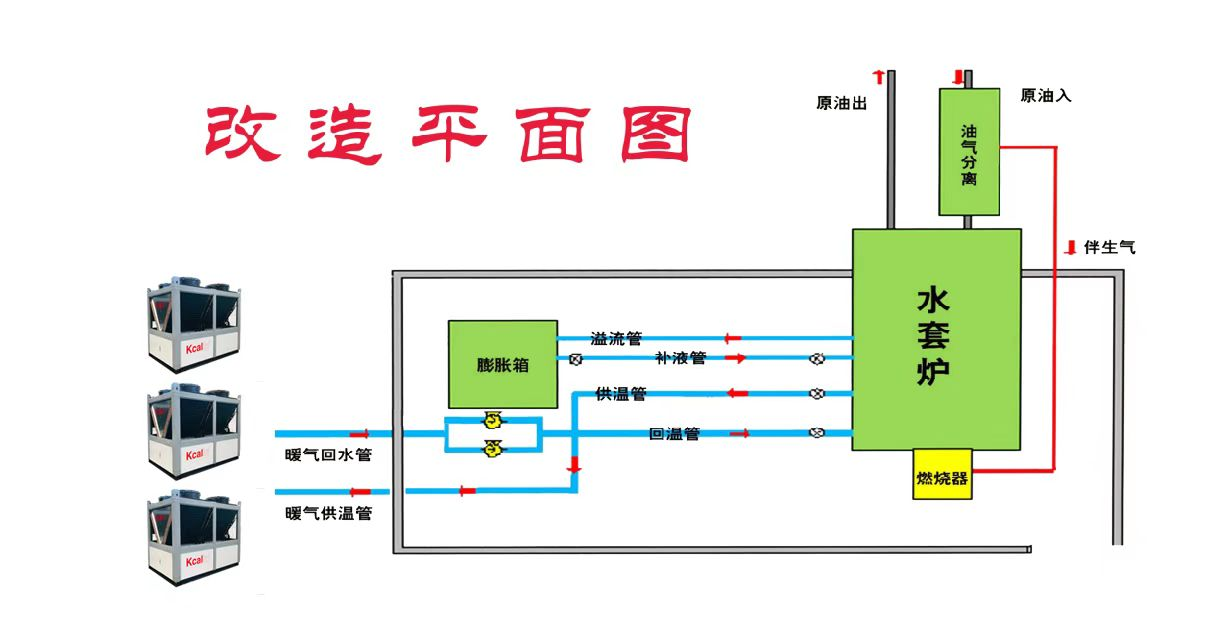

Take the jacket furnace for crude oil heating as an example: the incoming crude oil is heated by the jacket furnace, and the associated gas separated from the oil-gas separator at the oil inlet enters the burner for combustion, and the water temperature of the jacket furnace rises; The crude oil passes through the heat exchange coil in the jacket furnace to exchange heat with the hot water in the furnace to raise the temperature. The heating hot water in the station comes from the jacket boiler and is circulated by the heating circulating pump.

Affected by the attenuation of associated gas, during the winter production process, the amount of associated gas separated from the oil and gas separator is unstable, and the water jacket boiler cannot work continuously and stably. The boiler is often shut down during the production process, requiring frequent patrol inspection by the operators, and repeatedly starting the heating, wasting manpower and material resources.

Disadvantages of this heating

Once the personnel fail to find it in time, the crude oil will be difficult to transport, and the heating pipeline in the station will be frozen and cracked to cause failure. Therefore, the following two problems should be solved:

1. Antifreeze in winter

2. Supplement and evaporation of heat transfer medium

Kcalin STS high-efficiency air-source heat pump technology is used to replace the original coal, gas, electric heating and other methods, and the heat source of the crude oil heating system is replaced by STS high-efficiency air-source heat pump. The original equipment and transmission pipeline can be put into use without change, with short construction period and low transformation cost.

(1)Eliminate fire source, improve safety, reduce equipment operation management pressure and operation management cost;

(2)Stabilize the heating source, ensure the continuous and stable heating of the heat source, and ensure safe production;

(3)Reduce patrol inspection and intelligent control of air source heat pump through intelligent management cloud platform to reduce labor costs;

(4)Improve the thermal efficiency, increase the heat utilization rate and reduce the use cost.

As shown above, the crude oil heating process transformation scheme is described as follows:

(1)Kcalin air source heat pump equipment is directly connected to the heating supply and return water pipelines in the original station, and the connection point is as shown in the figure;

(2)The original temperature supply and circulation pipeline can be used continuously, and the transformation cost is low;

(3)Kcalin air source heat pump equipment can realize defrosting function in high humidity climate;

(4)-25℃Continuous and stable heating.

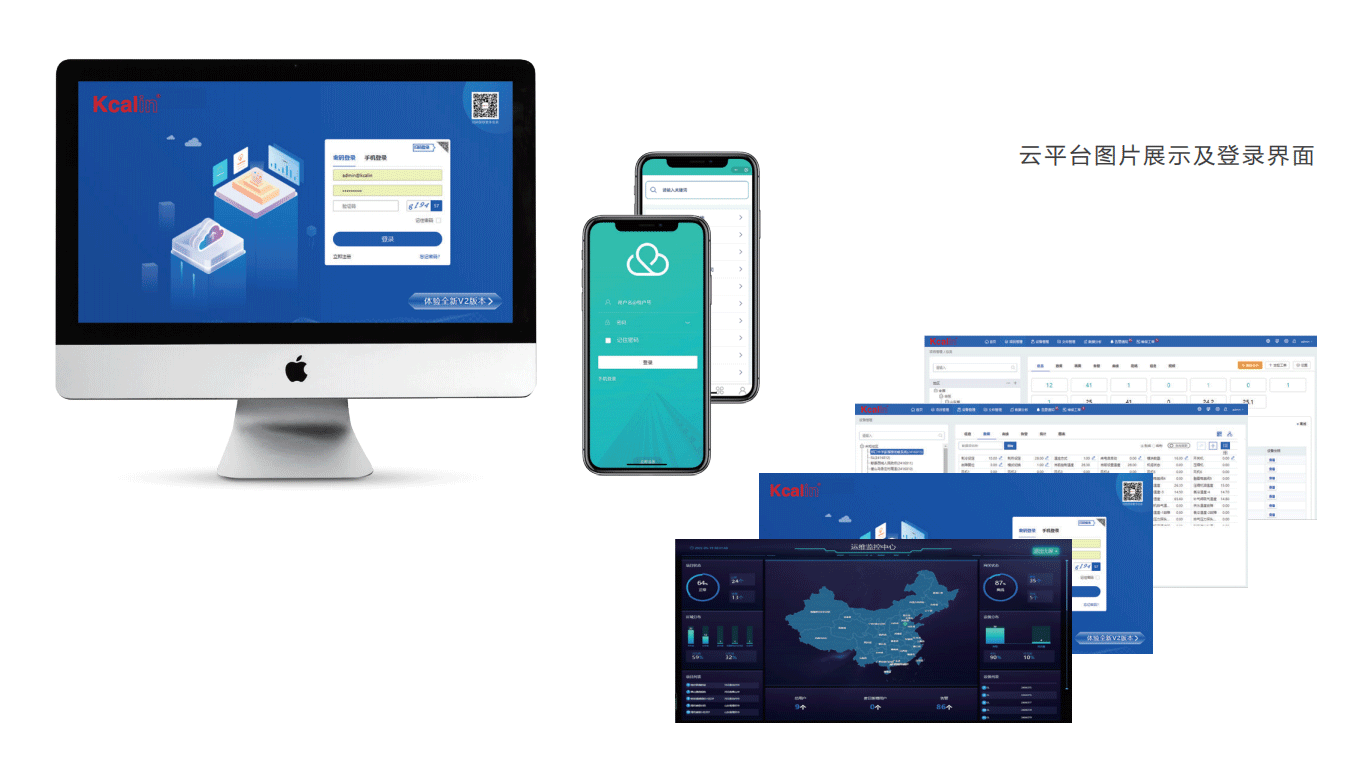

Introduction to operation interface

Kcalin air source heat pump can adjust and control the water inlet and outlet temperature and other working conditions of the unit through the touch screen control system of the unit itself, and can also timely monitor the operation status of the unit and adjust the parameters through the cloud platform or mobile phone Kcalin cloud terminal program to realize the unattended function.

Comparison before and after transformation

|

Before transformation |

After transformation |

|

Frequent cease-fire, unable to continue normal work |

Continuous and stable operation |

|

Antifreeze in winter |

Intelligent frost control, no need to consider antifreeze |

|

Need human patrol management |

Centralized control and intelligent management to reduce labor costs |

|

Low thermal efficiency and high use cost |

High energy efficiency ratio, saving more than 60% energy consumption |

|

Fire sources need to be eliminated and safety improved |

Modular structure, more flexible unit selection and layout With the help of the original circulation system, the cost is low and the quantity is small |

Recommendations

Solution to mine high temperature heat hazard

Thermal power industry waste heat utilization solution

Solution for waste heat utilization in chemical industry

Flexible air source heat pump

Characteristics and uses of refrigerants of air source heat pump

Kcalin's popular new products made a grand appearance at "Beijing International Fresh Air Purificati

Comment