With the increasing emphasis on environmental protection and resource conservation in China, energy conservation and emission reduction have become important tasks for various industries. In the mining industry, the application of an innovative technology is quietly changing the traditional way of energy utilization, which is the recovery and utilization of residual heat from mine compressed air. Today, let's explore this new path of energy conservation and emission reduction together, and see how the waste heat from mine compressed air can be turned into treasure.

Mine ventilation waste heat, as the name suggests, refers to the heat generated during the ventilation process of a mine. In the past, this heat was often overlooked and even considered as waste heat directly emitted into the atmosphere. However, with the development of technology, people have discovered that these "waste heat" are actually a huge energy treasure trove.

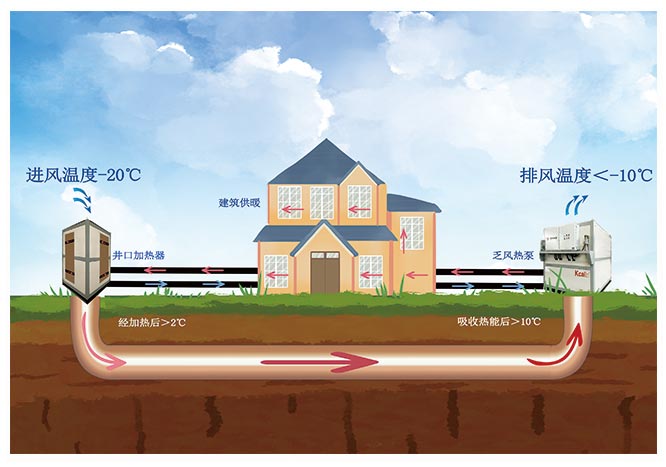

The recovery and utilization technology of mine ventilation waste heat is to collect the heat generated during the mine ventilation process through a series of equipment and technical means, and use it for heating, bathing hot water, industrial water heating and other fields. This not only reduces energy consumption, but also lowers environmental pollution, achieving a win-win situation of economic and environmental benefits.

The following are several highlights of mine compressed air waste heat recovery and utilization:

Energy conservation and emission reduction: By recycling the residual heat of mine compressed air, the use of traditional energy sources such as coal and gas can be significantly reduced, thereby reducing the emissions of carbon dioxide and other harmful gases and achieving the goal of energy conservation and emission reduction.

Economic benefits: The investment return period of the mine compressed air waste heat recovery and utilization system is relatively short, usually recovering costs within 2-3 years. In the long run, it has saved a lot of energy costs for enterprises.

Environmentally friendly: reduces dependence on fossil fuels, lowers greenhouse gas emissions, helps improve the mining environment, and achieves green and sustainable development.

Stable and reliable: The mine compressed air waste heat recovery and utilization system is not affected by external climate and can operate stably throughout the year, providing continuous thermal energy supply for the mine.

So, how does the residual heat from mine ventilation turn waste into treasure? Here are a few key steps:

Collection: By installing specific heat exchangers, the hot air and cold water in the mine ventilation ducts are exchanged to collect heat.

Transmission: Transfer the collected heat through pipelines to places that require heating or warming.

Utilization: The transferred heat is used for heating, bathing hot water, industrial water heating, etc., to achieve the reuse of thermal energy.

Control: Through an intelligent control system, real-time monitoring and adjustment of the mine compressed air waste heat recovery and utilization system are achieved to ensure efficient and stable operation of the system.

The technology of recovering and utilizing residual heat from mine compressed air has opened up a new path for energy conservation and emission reduction for mining enterprises. It not only helps enterprises reduce operating costs and improve economic efficiency, but also contributes to China's environmental protection cause. With the continuous promotion and application of this technology, we have reason to believe that mine compressed air waste heat will become an important force for green development in the mining industry, contributing to the construction of a beautiful home.

Comment