With the increasingly severe energy problem and the gradual improvement of environmental protection requirements, mining enterprises are facing greater challenges in the field of winter heating. The traditional heating method not only consumes a huge amount of energy, but also brings a large amount of greenhouse gas emissions, increasing the operating costs and environmental burden of enterprises. In this context, mining air heating units, especially innovative applications based on exhaust heat pump systems, are becoming an effective way to solve these problems.

Working principle of mining air heating unit

Mining air heating unit is a heating equipment specially designed for the mining environment, with the purpose of providing stable heat sources for underground work and living areas in cold seasons. Traditional mining air heating units usually rely on electricity or fuel for direct heating. Although this method is simple and easy to use, it has high energy consumption, high cost, and does not meet the requirements of modern green development.

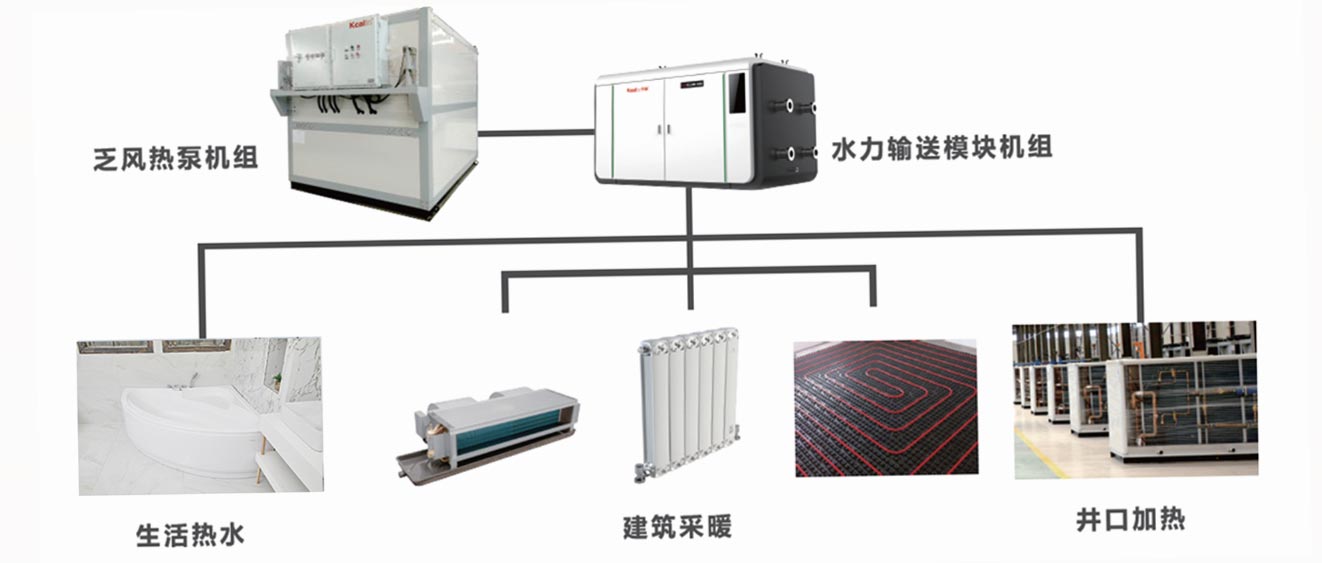

Unlike traditional systems, the exhaust heat pump system utilizes the waste heat resources of exhaust air inside the mine, greatly reducing energy consumption. Lack of air refers to the air discharged from the return airway of a mine, usually carrying a large amount of waste heat. The exhaust heat pump system extracts heat from the exhaust air through a heat exchanger and converts it into high-temperature heat energy through heat pump technology for heating the air. The heated air is transported to various heating areas in the mine, achieving energy-saving and efficient heating effects.

Application advantages of exhaust heat pump system

Energy saving and environmental protection: The exhaust heat pump system achieves the effect of "turning waste into treasure" by recovering the waste heat from the exhaust air in the mine. Compared to traditional electricity or fuel heating methods, this approach greatly reduces energy consumption and greenhouse gas emissions, which is in line with the current policy direction of energy conservation and emission reduction.

Reducing operating costs: As the exhaust heat pump system mainly relies on the waste heat of exhaust air inside the mine and does not require continuous input of external energy, it significantly reduces the heating costs of the enterprise. Especially in the case of significant fluctuations in energy prices, the cost advantage of exhaust heat pump systems is particularly evident.

High system stability: The exhaust heat pump system has mature technology, stable operation, and is suitable for complex mine environments. The equipment is easy to maintain and has a long service life, providing a reliable heating solution for enterprises.

Improving working environment: The stable heating provided by the exhaust heat pump system has improved the working environment inside the mine. This not only improves the work comfort of underground workers, but also helps to improve production efficiency and ensure safe production.

Taking the Lu Ning coal mine as an example, the mining enterprise is located in a cold region with an urgent demand for winter heating. In the past, enterprises mainly relied on coal-fired boilers for heating, which not only consumed a large amount of energy but also caused serious pollution emissions, putting considerable pressure on local environmental governance. After introducing the exhaust heat pump system, the situation has been significantly improved.

The enterprise has installed a waste air heat pump system at the return airway of the mine, which achieves heating for the entire mine through the recovery and utilization of waste heat from the waste air. The renovated system not only reduces coal consumption and annual emissions of carbon dioxide and sulfides, but also saves heating costs for enterprises. According to statistics, this renovation project has saved the enterprise 30% of heating costs annually and improved the air quality inside the mine, providing better environmental protection for workers' safe operations.

The application of mining air heating units, especially exhaust heat pump systems, represents an important innovation in the field of mining heating. Through the efficient utilization of existing resources within the mine, this system has brought results to energy conservation, emission reduction, cost reduction, and improved production environment for enterprises. With the further promotion and application of technology, exhaust heat pump systems are expected to become the heating choice for more mining enterprises, making greater contributions to the green development of the industry.

Comment