With the continuous growth of energy demand, mining, as an important field of energy production and supply, urgently needs to find innovative methods to improve energy utilization efficiency. In this context, the recovery of waste heat from mine return air has become a leading technology for efficient utilization of mining energy, providing new possibilities for exploring the future energy treasure of mining.

The large amount of exhaust gas and waste heat generated during the production process of mines often become neglected energy resources. Especially the high temperature and humidity air contained in the mine return air, if not effectively recycled, will lead to energy waste and environmental burden. Therefore, how to fully tap the energy potential of mine return air waste heat has become an urgent problem to be solved in the current mining industry.

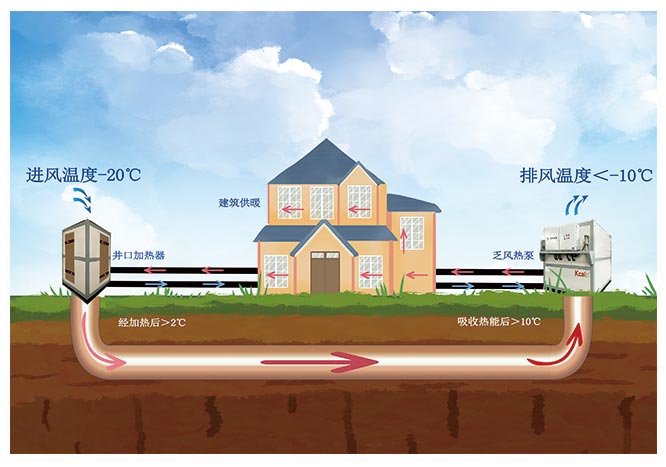

The mine return air waste heat recovery system effectively recovers and converts the high-temperature and high humidity energy in the mine exhaust gas into usable heat energy through a series of heat exchange, energy conversion, and system optimization processes. Its basic working principle includes:

Waste gas pretreatment: In mines, the waste gas may contain impurities and high humidity. In order to ensure the normal operation of the waste heat recovery system, it is necessary to carry out waste gas pretreatment, including dust removal, dehumidification and other processes.

Heat exchange process: The pre treated exhaust gas enters the heat exchanger and exchanges heat with fresh air or other media. During this process, the heat in the exhaust gas is transferred to the cooling medium, causing it to heat up.

Energy conversion: Through heat exchange, the energy released from high-temperature and high humidity exhaust gases is converted into thermal energy, which is provided to subsequent energy utilization systems, such as heating systems, hot water production, etc.

System optimization: In order to achieve a greater degree of energy recovery, the mine return air waste heat recovery system also needs to undergo system optimization, including intelligent design of the control system, introduction of recycling technology, etc., to improve the overall efficiency of the system.

Application fields of mine return air waste heat recovery system

Mining operations: During the mining process, a large amount of high-temperature exhaust gas is generated. Through the recovery system, the energy in these exhaust gases can be reused for energy supply in the internal equipment of the mine, improving the energy efficiency of the entire mining process.

Mine ventilation system: The mine ventilation system is an indispensable part of mine production. By recovering waste heat from the ventilation system, it can not only improve the energy efficiency of the ventilation system, but also provide additional energy support for the interior of the mine.

Residential areas for mine workers: The residential areas for mine workers can also benefit from the recycling system. By using waste heat for heating, hot water, and other purposes, the comfort of worker residential areas can be improved while reducing energy costs.

Technical advantages of mine return air waste heat recovery system

Energy conservation and emission reduction: The introduction of mine waste heat recovery system effectively reduces reliance on traditional energy, reduces energy consumption in mining production, and achieves the goal of energy conservation and emission reduction.

Improving mining production efficiency: By recovering energy from exhaust gas, not only does it provide additional energy support for the interior of the mine, but it also improves the overall efficiency of mining production and reduces production costs.

Environmentally friendly: The application of mine waste heat recovery system helps to reduce greenhouse gas emissions, reduce the impact on the surrounding environment, and is in line with the sustainable development concept of green mining.

Technological innovation and future prospects

Intelligent control technology: In the future, the mine waste heat recovery system is expected to introduce more intelligent control technology. Through sensors and adaptive control systems, real-time monitoring and adjustment of system operation can be achieved, improving the overall performance of the system.

Recycling technology: In order to better utilize the heat energy in exhaust gas, future mine waste heat recovery systems may introduce better recycling technologies, including cascade utilization, multi-level recovery, etc., to improve the comprehensive energy utilization efficiency.

Multi energy collaboration: With the trend of diversified energy development, future mine waste heat recovery systems may collaborate with other energy systems to achieve efficient utilization of multiple energy sources and provide more stable and reliable energy security for mining production.

The mine return air waste heat recovery system, as an innovative energy utilization in the mining industry, provides new ideas and possibilities for the sustainable development of the mining industry. By excavating the energy treasure in the mine return air, not only can energy utilization efficiency be improved, production costs reduced, but also environmentally friendly protection can be achieved. In the future, technological innovation will continue to promote the development of mine return air waste heat recovery systems, opening up broader prospects for the efficient utilization of mining energy. Let us join hands to embrace the future of green energy and jointly build a sustainable mining ecosystem.

Comment