In modern industry, energy is the lifeline of production and an important factor in environmental protection and sustainability. In order to better utilize energy and improve energy efficiency, the technology of recovering waste heat from mine exhaust air has emerged. This technology not only reduces energy costs, but also helps to reduce negative impacts on the environment, realizing the dual value of energy.

The exhaust heat recovery technology is a method of providing additional energy by recovering and reusing waste heat generated in mining production. In the mining industry, exhaust heat usually refers to the high-temperature waste heat discharged through the ventilation system. This type of waste heat is usually wasted, but through waste air waste heat recovery technology, it can be captured and reused, thereby improving energy efficiency.

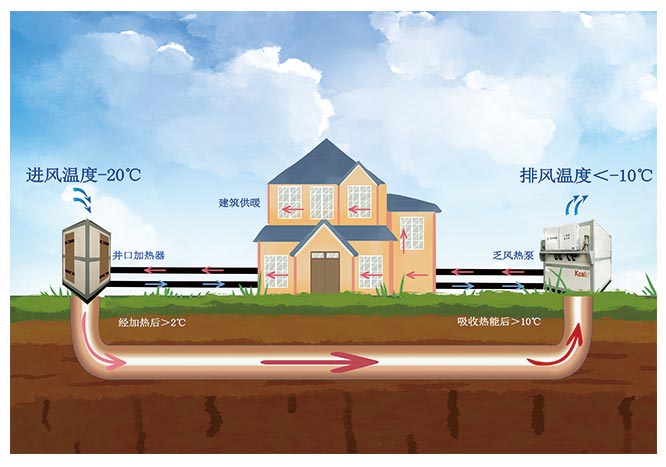

The basic principle of waste heat recovery technology for exhaust air includes the following steps:

Waste heat capture: In the mine ventilation system, hot air waste heat is captured through equipment such as heat exchangers and transferred to the next step.

Thermal energy conversion: The captured waste heat is converted into usable thermal energy, usually steam or hot water, through the exhaust air heat pump unit.

Reuse: The converted heat energy can be used for various purposes, such as heating, power generation, or other industrial processes, to achieve energy reuse.

The waste heat recovery technology for exhaust air has a wide range of applications in the mining industry and is also applicable to other industrial fields. The following are some common application areas:

Heating: By converting the waste heat of exhaust air into hot water or steam, it can be used to heat the working area or surrounding areas in the mine, improving the comfort of the working environment.

Electricity production: Through waste heat recovery technology, waste heat can be used for power generation, reducing power costs and reducing dependence on traditional fuels.

Industrial process: Waste heat from exhaust air can be used for heat treatment, drying, and other operations in mining processes to improve production efficiency.

Greenhouse agriculture: In greenhouse agriculture, exhaust heat can be used to maintain the temperature inside the greenhouse and create a suitable growth environment.

The exhaust heat recovery technology has multiple advantages, making it highly popular in industrial applications:

Saving energy costs: By recycling and reusing waste heat, enterprises can reduce energy costs and improve economic efficiency.

Reducing greenhouse gas emissions: Reducing dependence on traditional energy and reducing greenhouse gas emissions such as carbon dioxide can help mitigate climate change.

Improving energy efficiency: The recovery of waste heat from exhaust air improves the energy efficiency of mining processes, reduces waste, and improves production efficiency.

Sustainability: By utilizing waste heat and recovering waste air heat, it helps to achieve sustainable development goals and reduce dependence on limited energy resources.

Mine exhaust heat recovery technology is a dual value method that can utilize energy. By recovering waste heat, it can not only reduce energy costs, improve energy efficiency, but also help reduce environmental impact and achieve sustainable development. In modern mining, this technology is increasingly valued, which not only contributes to the economic benefits of enterprises, but also helps to achieve environmental protection and sustainability goals. Through wider application and continuous technological innovation, the waste heat recovery technology of exhaust air will play a more important role in the future, bringing dual benefits to mining production.

Comment