With the increasing demand for renewable energy and environmental protection technologies, various industries are seeking innovative methods to reduce energy waste and environmental impact. The mining industry has always been an industry with huge energy consumption, but now, with the help of heat pipe mine exhaust heat recovery schemes, the coal mining industry has also taken sustainable development steps.

The coal mining industry has always been one of the main areas of energy consumption, but it also faces energy waste and environmental issues. During the mining process, massive mechanical and engineering equipment generates a large amount of waste heat. These waste heat not only waste valuable energy resources, but also have a negative impact on the environment. At the same time, many coal mines are located in remote areas and the power supply is unstable, which makes the energy problem even more prominent.

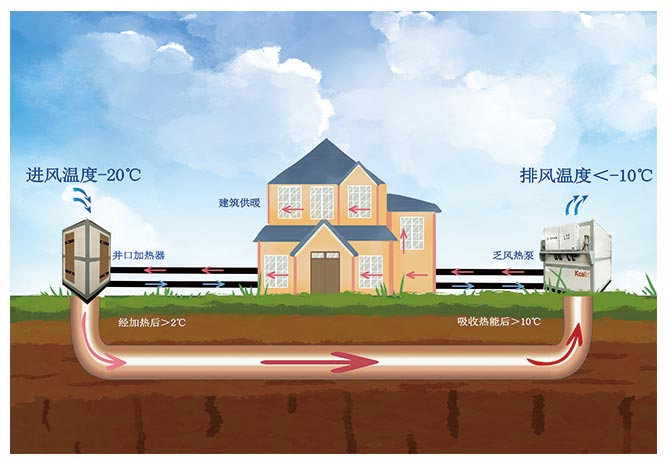

The heat pipe type mine exhaust heat recovery is an innovative technology based on waste heat recovery, which can reuse the heat energy generated underground in coal mines. The working principle is as follows:

1、 The exhaust heat pump system absorbs heat energy from the waste heat generated by mechanical and engineering equipment in the mine.

2、 The heat pipe system transfers the absorbed heat energy to the area that needs to be heated, such as the HVAC system of mining equipment, the heating system of the working face, or the hot water system.

3、 The heat pipe recovery system achieves efficient energy recovery through this method, converting waste heat into useful energy and providing it for related purposes at mining sites, thereby reducing energy costs and improving energy utilization efficiency.

The application of this technology in the mining industry has brought about new changes.

Energy saving: The heat pipe type mine waste heat recovery system effectively reduces waste heat waste, improves energy utilization efficiency, and reduces operating costs.

Environmental benefits: Waste heat recovery not only reduces energy waste, but also helps to reduce environmental pollution. By reducing greenhouse gas emissions and other pollutants, coal mining enterprises can better fulfill their social responsibilities.

Improving production efficiency: Utilizing recycled waste heat to meet the heating and hot water needs of mining sites can help improve production efficiency. Workers work in a more comfortable environment and have higher production efficiency.

Sustainable development: Heat pipe type mine waste heat recovery helps the coal mining industry achieve sustainable development. It reduces dependence on limited energy resources, prolongs the lifespan of the coal mining industry, and helps establish more environmentally friendly mines.

The heat pipe type mine exhaust heat recovery technology, as a green energy technology, provides a sustainable development path for the coal mining industry. By recycling waste heat, reducing energy consumption, improving production efficiency, and reducing environmental impacts, the coal mining industry can achieve more sustainable development and contribute to future energy challenges. The coal mining industry should actively adopt this technology and strive for the goal of sustainable development.

In the future, we are expected to see more coal mining enterprises adopt heat pipe mine exhaust heat recovery technology, jointly committed to building a more environmentally friendly and sustainable coal mining industry. No longer allowing exhaust air to become waste gas, heat pipe technology has stood at the forefront of sustainable development, injecting new vitality into the coal mining industry.

Comment