Energy efficiency and sustainability have become hot topics in various industries. In this context, waste heat recovery technology has received widespread attention as an important energy utilization method. Especially in the mining industry, the exhaust heat pump unit, as an innovative waste heat recovery technology, is gradually emerging.

Exhaust Air Heat Pump Unit: A New Way to Recover Heat Energy

In mines and mine operations, a large amount of exhaust gas and waste heat are usually discharged into the atmosphere. These exhaust gases contain valuable thermal energy and are traditionally considered a waste of energy. However, the emergence of exhaust air heat pump units has changed this situation. They are a waste heat recovery technology aimed at capturing and reusing the thermal energy in the exhaust air, providing heating and hot water for thermal energy needs.

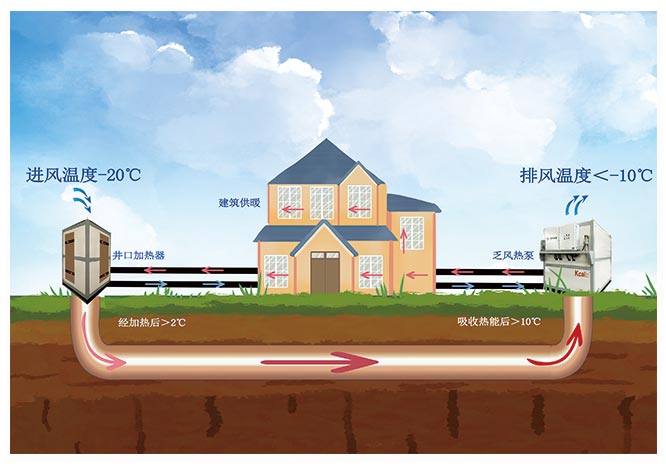

The working principle of the exhaust air heat pump unit is based on heat pump technology, and its basic steps are as follows:

Exhaust gas collection: Exhaust gas, also known as exhaust gas, refers to the exhaust gas generated during mining or mine operations. These exhaust gases contain thermal energy, but are usually discharged into the atmosphere.

Evaporation and heat transfer: The exhaust air is directed to the evaporator of the exhaust air heat pump unit. In the evaporator, the heat energy in the exhaust air is used to evaporate low boiling point working fluids, such as refrigerants. This process absorbs the heat from the exhaust gas, cools it, and causes the refrigerant to evaporate into a gas.

Compression and heating: Gas refrigerant enters the compressor and is compressed into a high-temperature and high-pressure state, thereby increasing temperature and pressure.

Condensation and heat release: High temperature and pressure gases pass through the condenser, releasing heat and transferring it to water supply or other working fluids. This causes the refrigerant to return to a liquid state.

Expansion and cooling: The liquid refrigerant passes through the expansion valve, reducing temperature and pressure, preparing to re-enter the evaporator and start a new cycle.

This process is constantly circulating, constantly converting the heat energy in the exhaust air into usable hot water, steam, or other forms of heat energy to meet the heating, hot water, and other needs inside the mine.

The exhaust air heat pump unit has many advantages and potential benefits in the mining industry, including:

Energy recovery: Through the exhaust air heat pump unit, the heat energy in the exhaust gas is recovered, greatly improving energy utilization efficiency.

Environmental benefits: The recovery and reuse of exhaust gas can help reduce carbon emissions in the mining industry, reduce environmental impacts, and meet sustainable development goals.

Economic benefits: Although the initial investment is relatively high, the long-term economic benefits of the exhaust air heat pump unit are obvious. The reduction of energy costs, extension of equipment lifespan, and improved working environment will improve production efficiency and bring more profits to the company.

Reducing heating burden: Traditional heating methods are expensive, while the operating cost of exhaust air heat pump units is relatively low, reducing the financial burden on mining companies.

Improving energy self-sufficiency: Mining companies can better self supply energy, reduce dependence on external energy supply, and increase self-sufficiency.

The exhaust heat pump unit, as an emerging technology, is still continuously developing. Scientists and engineers continue to research and improve systems to improve efficiency, adapt to different operating conditions, and reduce costs.

The exhaust heat pump unit represents the future of energy innovation and sustainability. It not only improves energy efficiency, but also reduces environmental impact. Mining companies should actively consider adopting this technology to achieve sustainable development goals and play a positive role in environmental protection and social responsibility. Clean heating not only brings economic benefits to mining, but also lays a solid foundation for the sustainable future of the entire industry. Let's work together for the future of clean heating.

Comment