As an important energy resource mining base, coal mining activities are often accompanied by a large amount of exhaust air and waste heat emissions. These emissions not only waste valuable energy resources, but also have a negative impact on the environment. However, through heat pump technology, we can effectively recycle and utilize these waste air heat, providing efficient heating for coal mines, while reducing energy consumption and environmental burden.

Exhaust Heat: Energy Waste in Coal Mines

In the process of coal mining, in order to ensure the air circulation in the working area and the safety of miners, it is often necessary to use powerful ventilation systems. These ventilation systems discharge toxic gases and dust from coal mines to the outside by extracting a large amount of air. At the same time, coal mining operations also generate a large amount of waste heat, such as mine drainage and mining machinery operation. However, these waste air and heat are often regarded as waste and directly discharged into the atmosphere, resulting in energy waste and environmental pollution.

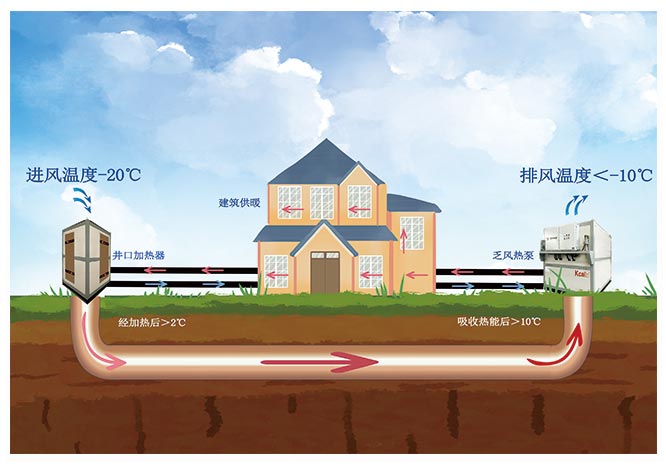

Heat pump technology is an energy utilization technology that can convert low-temperature heat sources into high-temperature heat energy. Its basic principle is to raise the heat in the low-temperature heat source to a sufficiently high temperature through cyclic processes such as evaporation, compression, condensation, and expansion to supply the heating system. In coal mines, heat pump technology can be used to recover waste heat from exhaust air and achieve efficient heating as follows:

Exhaust air recovery: The exhaust air in the coal mine is heat recovered through a heat exchanger to extract the heat from it.

Evaporation and compression: The recovered heat is used to evaporate and cool the working medium, and then the temperature is increased by compression.

Heat exchange and heating: The heated working fluid is transferred to the heating system through a heat exchanger to heat the working area of the coal mine.

Condensation and expansion: After heat exchange, the working fluid cools down, and then returns to the evaporation state through the expansion device, ready for reuse.

This cycle process enables the recovery and conversion of low-temperature exhaust heat from coal mines into useful high-temperature thermal energy, achieving effective energy utilization.

The application of heat pump technology in coal mine heating can improve heating efficiency, reduce energy waste and environmental pollution. The following are some practical application cases of heat pump technology in coal mine heating:

Underground mining heating: Underground mining companies introduce heat pump technology to recover the waste heat of underground exhaust air for heating. This not only improves heating efficiency, but also reduces energy consumption in the mining process, helping the company save costs.

Heating of open-pit mining office areas: The open-pit mining company located in cold regions adopts an air source heat pump system to recover the waste heat generated during the open-pit mining process and the low-temperature energy in the air for heating the office area. This measure not only improves the working environment for employees, but also reduces the company's heating costs.

Mine drainage heat recovery: Coal mining companies use heat pump technology to recover waste heat from mine drainage and use it for heating underground miners' dormitories. This innovative application not only improves heating efficiency, but also reduces the thermal pollution of drainage to the environment.

Heat pump technology has obvious advantages in coal mine heating:

High efficiency: Heat pump technology can efficiently recover waste heat from exhaust air, convert it into high-temperature heat energy, and provide stable heating.

Energy conservation: By recycling waste heat and exhaust air, heat pump technology reduces energy waste and dependence on fossil fuels.

Environmental protection and emission reduction: Heat pump technology does not generate exhaust emissions, which helps to reduce greenhouse gas emissions and meets environmental regulations.

Multi energy utilization: Heat pump technology can utilize various low-temperature heat sources, including underground thermal energy, water source thermal energy, etc., to achieve multi energy utilization.

As an important energy resource mining base, coal mines have always received attention to their energy waste issues. However, through the application of heat pump technology, coal mines can recycle the waste heat of exhaust air, achieve efficient heating, reduce energy consumption and environmental burden. The advantages of heat pump technology such as high efficiency, energy conservation, environmental protection, emission reduction, and multi energy utilization make it an ideal choice for coal mine heating. With the continuous progress of technology and the pursuit of sustainable development in the coal mining industry, it is expected that heat pump technology will play an increasingly important role in the field of coal heating, bringing a sustainable future to the coal mining industry.

Comment