As an important coal producing area in China, the waste heat resources generated by the mine system in Shanxi region have been ignored. However, these waste air and waste heat contain enormous potential, which can be utilized reasonably to not only provide thermal energy for the mine, but also create economic benefits and have a positive impact on the environment.

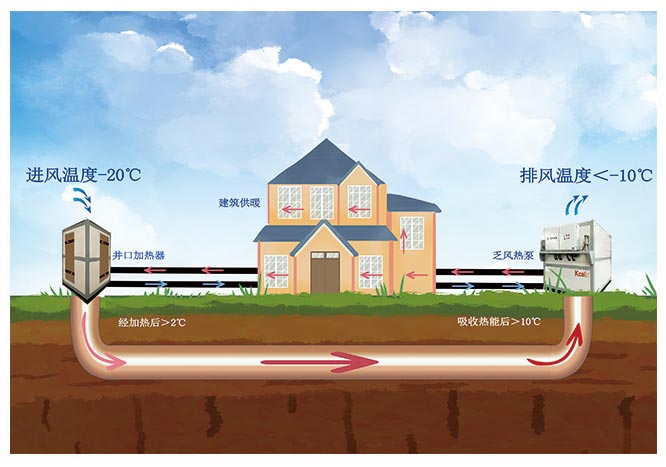

Establishing a waste heat recovery system for exhaust air is a key step in utilizing waste heat from exhaust air. This system includes heat exchange equipment, heat pump technology, pipeline transportation systems, etc. Through heat exchange equipment, the waste heat of exhaust air can be transferred to the working medium (such as water or industrial gas), and then heat pump technology can be used to upgrade low-temperature heat energy into high-temperature heat energy, which is supplied to heating and heating equipment in the mine. With the assistance of the pipeline transportation system, the recovery and utilization of waste heat from exhaust air can be achieved.

The winter in Shanxi region is cold, and heating equipment is needed inside the mine to provide a comfortable working environment for miners. The exhaust heat recovery system can provide a heat source for mine heating, reduce the use of other energy sources, and save energy costs. At the same time, this is also beneficial for improving the work efficiency and production quality of miners.

There is a high demand for domestic and bathing water for employees in the mine. The exhaust heat recovery system can use the recovered heat energy for hot water supply to meet the daily living needs of mine employees. This not only improves the quality of life for employees, but also reduces energy costs.

In summer, the temperature inside the mine increases and refrigeration equipment is needed to reduce the temperature. The exhaust heat recovery system can discharge heat from the mine during summer, achieving energy-saving cooling effects and improving the comfort of the working environment.

Economic Benefit Assessment

Energy cost savings: Through the application of a waste heat recovery system for exhaust air, the recovered thermal energy can be used for heating, heating, and cooling needs inside the mine, thereby reducing the cost of energy use. Compared to traditional energy sources such as electricity and coal, the economy of recycling waste heat from exhaust air is higher.

Short investment payback period: Although establishing a waste air and waste heat recovery system requires a certain amount of investment, due to its ability to reduce energy costs and improve miners' work efficiency, the investment payback period is usually short. This means that economic returns can be obtained in the short term.

Environmental benefits: By recycling and utilizing waste heat from exhaust air, energy consumption in mines is reduced, carbon emissions are reduced, and the impact on the environment is reduced. This helps to improve local air quality, reduce greenhouse gas emissions, meet environmental requirements, and enhance the social image of enterprises.

Resource sharing: The exhaust air and waste heat inside the mine can not only meet the needs of the mine, but also provide thermal energy resources to the surrounding areas. This resource sharing model can create greater economic benefits, promote regional energy co construction and sharing, and contribute to local economic development.

Comment