Energy shortages and environmental pollution have become common challenges. In many underground mines and tunnels, due to the existence of depleted air resources and a large amount of waste heat, how to efficiently utilize these resources and achieve energy recovery and reuse has become an important research topic. The ventilation shaft exhaust heat recovery heat pump heating system is a potential solution. This article will provide a detailed introduction to the design principle of the system and evaluate its performance.

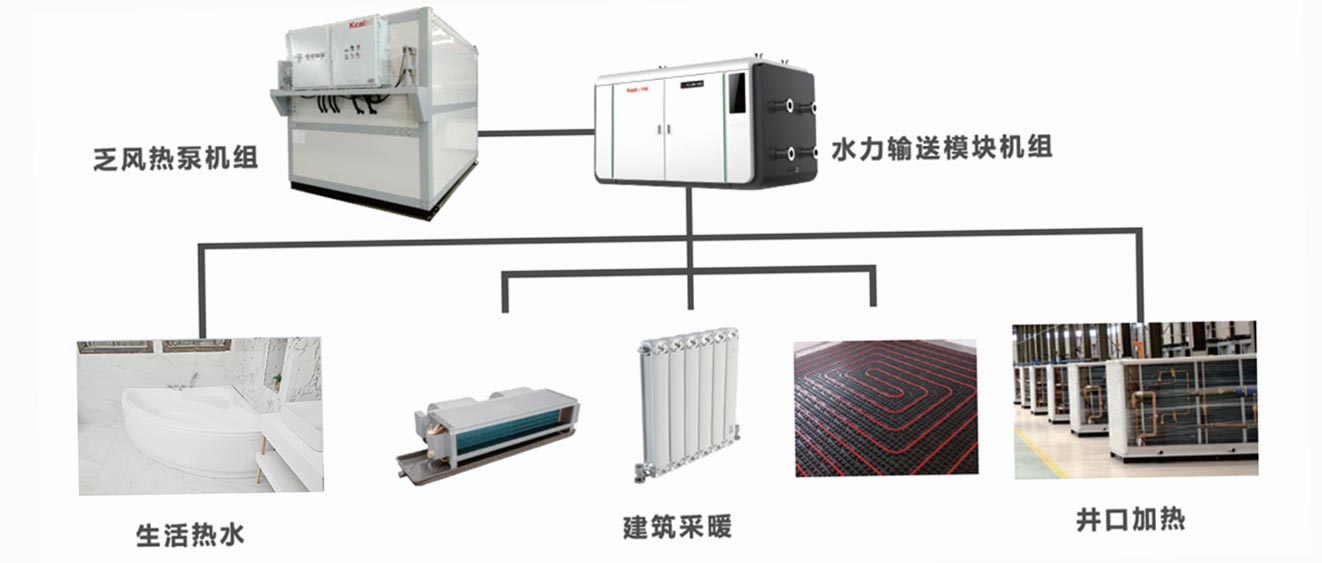

The ventilation shaft exhaust heat recovery heat pump heating system mainly consists of the following parts:

Ventilation shaft exhaust air recovery device: used to collect exhaust air resources in the ventilation shaft and import them into the system.

Heat pump: Through processes such as evaporation, compression, condensation, and expansion, it achieves the recovery and conversion of waste heat, converting low-temperature heat energy into high-temperature heat energy.

Hot water supply system: The high-temperature hot water generated by the heat pump is supplied to buildings or other facilities for heating or hot water use.

Working principle: The exhaust air resources in the ventilation shaft are collected by the recovery device, and after pre-treatment, they enter the heat pump system. In a heat pump, the low-temperature thermal energy of exhaust air resources evaporates by absorbing heat from the external air through the evaporator, forming low-temperature and low-pressure steam. Then, the steam is compressed and releases high-temperature and high-pressure heat through the condenser. By adjusting the pressure through an expansion valve, hot water with high temperature and pressure is formed, which is supplied to the hot water supply system to meet the heating and hot water needs of buildings or facilities.

Performance evaluation of heat pump heating system for exhaust heat recovery from ventilation shafts

Energy utilization efficiency: The main purpose of the ventilation shaft exhaust heat recovery heat pump heating system is to recover and utilize waste heat resources, and improve energy utilization efficiency. By analyzing and optimizing the energy conversion losses of each link in the system, energy utilization efficiency can be improved and efficient waste heat recovery can be achieved.

Economic evaluation: When designing a ventilation shaft exhaust heat recovery heat pump heating system, an economic evaluation is required. Including considerations of initial investment cost, operation and maintenance cost, and energy-saving benefits. By comprehensively evaluating costs and benefits, the economic feasibility and payback period of the system can be determined.

System stability: The ventilation shaft exhaust heat recovery heat pump heating system needs to operate stably in complex underground environments. The stability of the system includes aspects such as the reliability of equipment operation, system security, and the ability to respond to unexpected situations. Reasonable design and backup measures are needed to ensure system stability and security.

Environmental impact assessment: The operation of the ventilation shaft exhaust heat recovery heat pump heating system will have certain environmental impacts, including noise, exhaust emissions, etc. It is necessary to conduct an environmental impact assessment and take corresponding measures to reduce adverse impacts on the environment and achieve environmentally friendly operation.

Application prospects: The ventilation shaft exhaust heat recovery heat pump heating system has broad application prospects in underground engineering such as coal mines and underground tunnels. These underground projects usually have abundant waste air resources and a large amount of waste heat, making them suitable for energy utilization using waste heat recovery and heat pump technology.

Economic and environmental advantages: By recovering the waste heat from the exhaust air of the ventilation shaft and converting it into thermal energy for heating, energy consumption can be reduced, the use of traditional energy can be reduced, thereby saving energy and reducing operating costs. At the same time, the efficient recovery of waste heat also helps to reduce environmental pollution and greenhouse gas emissions, achieving the utilization of clean energy.

Stability of energy supply: The ventilation shaft exhaust heat recovery heat pump heating system can operate stably in the underground environment, unaffected by factors such as climate and weather, ensuring the stability of energy supply and providing reliable energy guarantee for underground engineering.

The ventilation shaft exhaust heat recovery heat pump heating system is a highly efficient technical solution for utilizing waste heat. By recovering waste heat and converting it into thermal energy supply, energy recovery and reuse are achieved. In terms of application prospects and advantages, this system has broad application prospects and multiple advantages. By applying this system, energy conservation and environmental protection can be achieved, promoting the sustainable development of underground engineering and the green and low-carbon development of urbanization. However, the design and performance evaluation of the system need to comprehensively consider multiple factors, including energy utilization efficiency, economy, system stability, and environmental impact. Through continuous technological innovation and system optimization, we can fully tap into the energy treasure in ventilation shafts, achieve sustainable energy utilization, and make positive contributions to future energy transformation and urban development.

Comment