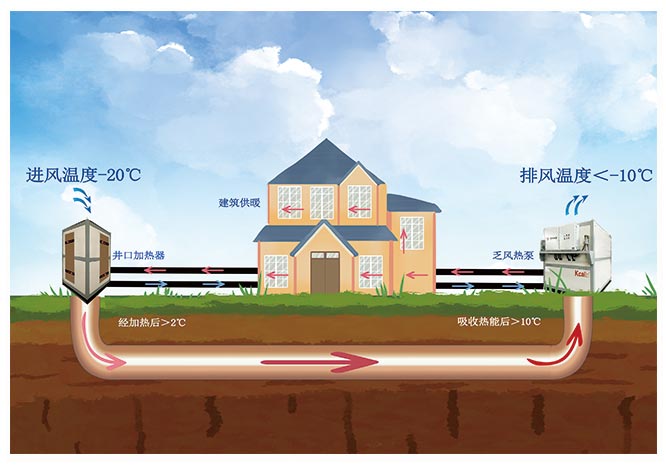

The heating of mine water inflow and waste heat requires certain equipment and technical support, among which the wellhead antifreeze hot air stove and exhaust air heat pump unit are two commonly used equipment.

Wellhead antifreeze hot air stove

The wellhead anti freezing hot air stove is a type of equipment used for mine water inflow and waste heat heating, mainly used to prevent the wellhead from freezing, while transferring waste heat to the air through a heat exchanger and heat to the heating area. This equipment mainly consists of a burner, heat exchanger, fan, water pump, etc. It flows hot water into the heat exchanger through natural or forced circulation. When the hot water comes into contact with air, heat is generated, and the hot air is sent into the room for heating.

The wellhead antifreeze hot air stove has the characteristics of easy installation, simple operation, and long service life. At the same time, it can automatically adjust the temperature to maintain a stable indoor temperature. In the heating of mine water inflow and waste heat, the anti freezing hot air stove at the wellhead can play an important role in reducing energy costs and improving heating efficiency.

Exhaust air heat pump unit

The exhaust air heat pump unit is a type of equipment that uses heat pump technology to heat up the waste heat of mine water, mainly composed of compressors, evaporators, condensers, expansion valves, etc. This equipment converts low-quality waste heat into high-quality heating energy through a heat pump cycle, achieving the goal of energy conservation, emission reduction, and reducing enterprise operating costs.

The exhaust air heat pump unit has the characteristics of good heating effect, stable operation, energy conservation and environmental protection. By using heat pump technology to convert waste heat from mine water into heating energy, not only can energy costs be effectively reduced, but also dependence on traditional energy can be reduced, achieving the goal of environmental protection and energy conservation.

In short, the wellhead antifreeze hot air stove and exhaust air heat pump unit are commonly used equipment in mine water inflow waste heat heating. They can effectively utilize waste heat resources, reduce energy costs for enterprises, and achieve the goals of energy conservation, emission reduction, and environmental protection. With the continuous development of technology and the widespread promotion of applications, these equipment are also constantly improving and upgrading, providing more reliable and efficient support for mine water inflow and waste heat heating.

In addition to the wellhead antifreeze hot air stove and exhaust heat pump unit, there are also other equipment that can be used for mine water inflow waste heat heating, such as mine ventilation systems and waste heat recovery systems. These devices can be selected and combined based on specific heating needs and resource conditions to achieve good heating effects.

At the same time, some technical support is needed for mine water inflow waste heat heating, such as thermodynamic calculations, pipeline design, control systems, etc. These technical support can maintain the stable and efficient operation of the heating system, thereby providing better services for enterprises.

In short, mine water inflow waste heat heating is a feasible way of energy conservation, emission reduction, and environmental protection. It can effectively utilize waste heat resources, reduce energy costs for enterprises, and also achieve the goals of environmental protection and energy conservation. The wellhead antifreeze hot air stove and exhaust air heat pump unit are commonly used equipment, which can provide efficient and reliable support for the heating system. In the future, with the continuous progress of technology and the continuous expansion of applications, mine water inflow waste heat heating will be more widely applied and promoted.

Comment