In industrial production, especially during cold seasons, ensuring the appropriate temperature of industrial premises is crucial for the normal operation of equipment and the work efficiency of workers. Traditional heating methods often have high energy consumption and low efficiency, making it difficult to meet the needs of modern industry. With the advancement of technology, air source heat pump units have gradually become the choice of industrial heaters as an efficient and environmentally friendly heating solution.

The demand and challenges of industrial heaters

Temperature demand: Temperature control in industrial premises not only affects the comfort of workers, but also directly affects the operation of production equipment and the quality of products. Especially in some precision manufacturing and chemical industries, small fluctuations in temperature can lead to production accidents or product quality issues.

Energy consumption cost: Traditional heating equipment such as fuel and gas boilers and electric heaters have high energy consumption and low efficiency, resulting in high operating costs. For large-scale industrial sites, energy consumption issues are particularly prominent.

Environmental requirements: With the increasingly strict environmental regulations, industrial enterprises need to consider their impact on the environment when choosing heating equipment. Traditional combustion heating equipment emits a large amount of carbon dioxide and other pollutants, which do not meet modern environmental standards.

Maintenance and management: The maintenance and management of industrial heating equipment is also an important consideration factor. Complex equipment requires regular maintenance, which increases management costs and human resource investment for enterprises.

The air source heat pump unit absorbs low-temperature heat energy from the air, uses a compressor to lift it to a high-temperature and high-pressure state, and then releases the heat through a condenser to provide the required heat for industrial sites. The working process includes the following steps:

Evaporator: absorbs heat from the air, causing the refrigerant to evaporate.

Compressor: Compress the evaporated refrigerant to increase its temperature and pressure.

Environmental requirements: With the increasingly strict environmental regulations, industrial enterprises need to consider their impact on the environment when choosing heating equipment. Traditional combustion heating equipment emits a large amount of carbon dioxide and other pollutants, which do not meet modern environmental standards.

Maintenance and management: The maintenance and management of industrial heating equipment is also an important consideration factor. Complex equipment requires regular maintenance, which increases management costs and human resource investment for enterprises.

The air source heat pump unit absorbs low-temperature heat energy from the air, uses a compressor to lift it to a high-temperature and high-pressure state, and then releases the heat through a condenser to provide the required heat for industrial sites. The working process includes the following steps:

Evaporator: absorbs heat from the air, causing the refrigerant to evaporate.

Compressor: Compress the evaporated refrigerant to increase its temperature and pressure.

Easy maintenance: The structure of the air source heat pump unit is relatively simple, with low failure rate and low maintenance cost. Daily maintenance mainly includes cleaning filters and checking refrigerant, which reduces maintenance workload compared to traditional combustion heating equipment.

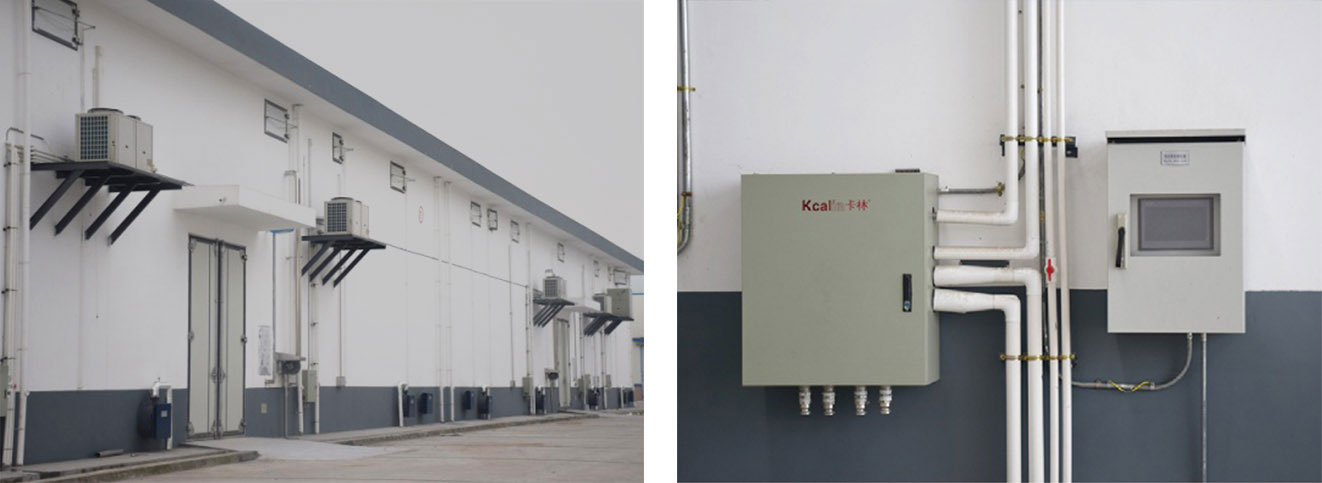

As an industrial heater, air source heat pump units, with their advantages of high efficiency, energy conservation, low-carbon environmental protection, flexibility and convenience, meet the efficient heating needs of modern industrial places. With the continuous progress of technology and the growth of market demand, air source heat pump units will play an increasingly important role in the future industrial heating field, helping enterprises achieve energy-saving and emission reduction goals, and promoting green development. By applying air source heat pump units reasonably, industrial enterprises can not only reduce operating costs, improve production efficiency, but also reduce environmental pollution, actively respond to the challenges of climate change, and move towards sustainable development.

Comment