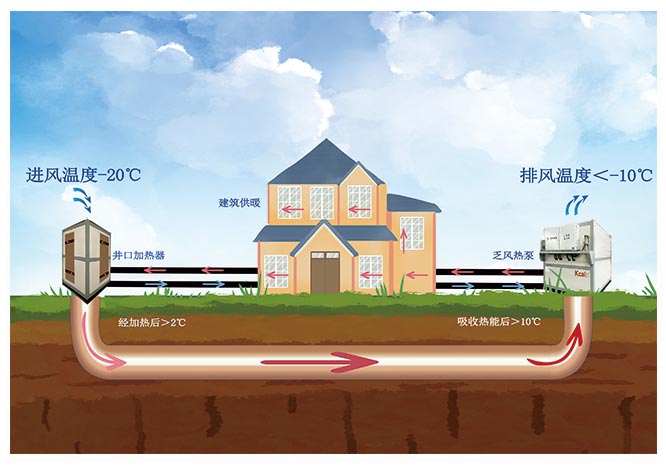

As a representative of the traditional energy extraction industry, how to effectively utilize resources and reduce waste is an important issue faced by coal mining enterprises. As an efficient and energy-saving new type of equipment, the fourth generation Kcalin exhaust heat pump unit is injecting new vitality and possibilities into the recovery of waste heat from coal mine return air.

During the coal mining process, a large amount of high-temperature and high humidity mine return air is discharged into the atmosphere, leading to energy waste and environmental pollution. The thermal energy resources contained in the mine return air are a potential valuable energy source. Through recycling and utilization, not only can the energy consumption cost of coal mines be reduced, but also the negative impact on the environment can be reduced.

As an important equipment in the coal mine return air waste heat recovery system, the fourth generation Kcalin exhaust heat pump unit has the following outstanding characteristics:

Efficient and energy-saving: By using heat pump technology, the high temperature and humidity energy in the mine return air can be converted into usable heat energy, improving energy utilization efficiency and reducing energy consumption costs.

Intelligent control: Equipped with an intelligent control system, it can automatically adjust according to the real-time situation of the mine return air, ensuring the stable operation of the system.

Stable and reliable: The fourth generation Kcalin exhaust heat pump unit is manufactured with high-quality materials and processes, which has good stability and reliability and can operate continuously for a long time.

Environmental protection and energy conservation: By recycling and utilizing the waste heat of mine return air, the dependence of coal mines on traditional energy is reduced, and the emissions of harmful gases such as carbon dioxide are reduced, which is beneficial for environmental protection.

Taking the Luning coal mine as an example, the introduction of the fourth generation Kcalin exhaust heat pump unit has achieved good results:

Energy conservation: The heat utilized by the exhaust heat pump unit each year is equivalent to saving a large amount of coal, greatly reducing energy consumption.

Cost reduction: Coal mine energy consumption is reduced, enterprises save a lot of production costs, and enhance competitiveness.

Environmental improvement: Reduced mine return air emissions, improved surrounding environmental quality, and had a positive impact on the health of residents and employees around the mining area.

The application of Kcalin's fourth generation spent air heat pump unit in mine return air waste heat recovery has achieved initial success, but there is still broader development space:

Technology constantly upgrades: Kcalin Company continuously innovates and invests in research and development, continuously improving the performance of the fourth generation of exhaust heat pump units to adapt to more coal mining scenarios.

Market demand growth: With the deepening of energy-saving and environmental protection concepts, the demand for energy-saving equipment such as exhaust heat pump units by mining enterprises will continue to increase.

Increased policy support: Policy support for energy conservation and emission reduction will also continue to increase, providing policy guarantees for the promotion of the fourth generation Kcalin exhaust heat pump units in the mining industry.

As an important equipment for recovering waste heat from mine return air, the fourth generation Kcalin exhaust heat pump unit provides strong support for coal mining enterprises to achieve energy conservation, emission reduction, cost reduction, and environmental improvement. In the future development, we believe that Kcalin's fourth generation spent air heat pump units will continue to play an important role in helping the mining industry move towards a more green and sustainable development path.

Comment