As an important energy extraction site, mines are often accompanied by a large amount of exhaust wind. How to effectively utilize the waste heat in these exhaust gases and improve energy utilization efficiency has become an urgent problem to be solved in the mining industry.

In the process of mining, in order to ensure the safety and ventilation needs of miners, it is usually necessary to introduce fresh air, while exhaust air is the waste air containing a certain amount of heat energy that is discharged. Traditionally, depleted wind has been simply discharged into the atmosphere, leading to energy waste and environmental pollution. In order to solve this problem, the waste heat utilization device for exhaust air has emerged.

Working principle of waste heat utilization device for exhaust air

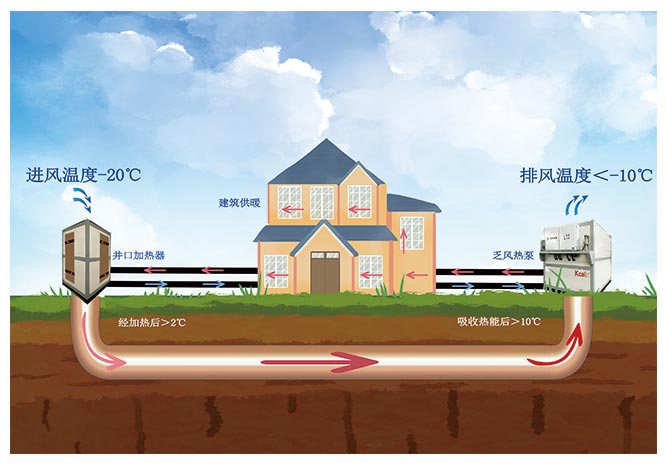

Collection and transportation of exhaust air: The exhaust air waste heat utilization device first collects exhaust air from the mine through the air duct system. In mines, the lack of air usually carries a certain temperature, which is due to the heat energy released by mechanical equipment, blasting operations, and other processes on the working face.

Application of heat exchanger: The collected exhaust air is exchanged through the heat exchanger for heat exchange. The function of a heat exchanger is to transfer the heat energy from the exhaust air to the working medium, which commonly includes water or other heat transfer fluids. Through this process, the temperature of the working medium increases and the temperature of the exhaust air decreases.

Energy conversion and utilization: The heated working medium carries the captured heat energy to the energy conversion device, which can be a thermal power generator, heat pump, and other equipment. In this step, the energy of the high-temperature working medium is converted into electrical energy or used to provide other energy needs.

Recovery of heat energy: After completing energy conversion, the temperature of the working medium decreases and becomes a cooling medium. At this point, the cooling medium passes through the heat exchanger and releases the remaining heat into the environment. This step aims to ensure the stable operation of the equipment and maximize the recovery of waste heat from the exhaust air.

Characteristics of waste heat utilization equipment for exhaust air

Efficient energy utilization: The waste heat utilization device of the mine exhaust achieves efficient utilization of thermal energy in the mine exhaust through heat exchange and energy conversion, improving energy utilization efficiency.

Environmental protection and emission reduction: Compared with traditional exhaust emission methods, the operation of the device can not only reduce greenhouse gas emissions, but also effectively reduce pollution to the atmospheric environment.

Multi functional and applicable: The waste heat utilization device for exhaust air can adapt to different working conditions and exhaust characteristics of mines, with certain flexibility and applicability, and can be customized according to needs.

Economical and practical: Although the initial investment of the waste heat utilization device for exhaust air is relatively high, its energy-saving and environmental benefits will gradually become apparent through long-term operation, and it has good economic efficiency.

Social benefits and prospects

Energy conservation: The operation of the waste heat utilization device for exhaust air makes the exhaust air in the mine no longer a simple waste gas, but a renewable energy source, providing considerable energy conservation for society.

Environmental protection: Reducing atmospheric pollution, through the promotion and application of waste heat utilization devices, is expected to contribute to environmental protection in the mining industry.

Technological innovation: The continuous improvement and innovation of the waste heat utilization device for exhaust air will promote the innovative development of related technologies and bring more environmental protection solutions to the mining industry.

By deeply analyzing the working principle and equipment characteristics of the waste heat utilization device in mines, we can clearly see its enormous potential in energy utilization and environmental protection. This innovative technology provides a sustainable development path for mining, which not only improves economic benefits but also contributes to the construction of a green mining environment. I believe that with the continuous progress of technology, the waste heat utilization device for exhaust air will be more widely applied and promoted in the mining industry.

Comment