In the coal mine ventilation system, there is often a phenomenon of lack of air, and if this large amount of waste heat resources are not fully utilized, it will become a waste of energy.

The coal mine ventilation system is a crucial component of coal mine production, however, it often accompanies the problem of lack of air, resulting in a large amount of waste heat that cannot be effectively utilized. In order to better address the issues of energy waste and environmental pollution, exhaust heat pump technology has emerged. Through thermal energy conversion, the waste heat of exhaust air is converted into usable energy, becoming a major highlight of the utilization of waste heat from coal mine ventilation shafts.

The problem of lack of air in coal mine ventilation shafts

Energy waste: The lack of air in the coal mine ventilation system results in a large amount of waste heat that cannot be fully utilized, becoming a waste of energy. Traditional treatment methods often only rely on heat dissipation or waste heat discharge, without properly converting this valuable waste heat resource.

Environmental pollution: Uneffectively utilized waste heat resources are often discharged into the environment in the form of waste heat, which not only wastes energy but also causes certain pollution to the surrounding environment. For today's environmentally friendly society, how to effectively utilize these waste heat resources has become an urgent problem to be solved.

Working principle of exhaust heat pump

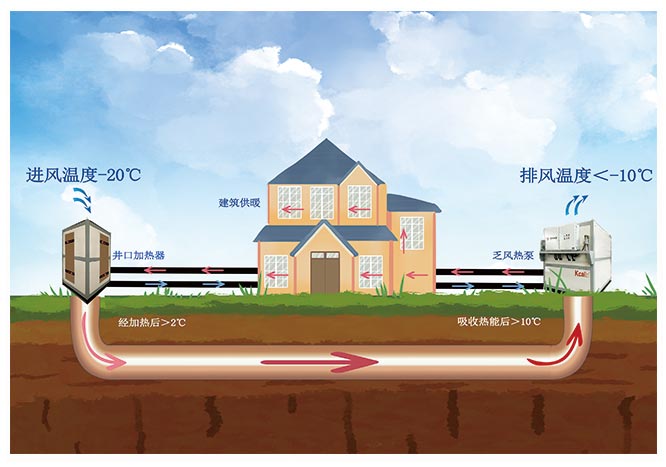

A depleted air heat pump is a system that can convert low-quality heat energy into high-quality heat energy. Its working principle is based on a heat pump cycle, which converts the heat energy provided by a low-temperature heat source (i.e. waste heat from exhaust air) into usable high-temperature and high-quality heat energy through processes such as evaporation, compression, condensation, and expansion, achieving energy regeneration and utilization.

Innovative application of exhaust heat pump in coal mine air shaft

Waste heat recovery: Through system design, the waste heat pump can efficiently recover the waste heat from the coal mine air shaft. This waste heat recovery not only reduces thermal pollution to the environment, but also fully utilizes this valuable thermal energy resource.

Green heating: The exhaust heat pump can be applied to the heating system in coal mines by converting waste heat into high-temperature water sources. This green heating method not only improves the efficiency of energy utilization, but also reduces the operating costs of coal mines, which has significant dual benefits for environmental protection and economy.

Electricity production: Through the use of exhaust heat pump technology, waste heat can be converted into electrical energy, providing self-sufficient electricity for coal mines. This self-sufficient energy model not only reduces the dependence of coal mines on external electricity supply, but also helps to reduce carbon emissions from electricity production.

The advantages of exhaust heat pumps

Efficient energy conversion: The exhaust heat pump is known for its efficient energy conversion characteristics. Through the heat pump cycle system, low-quality waste heat from exhaust air can be quickly converted into high-quality energy, improving energy utilization efficiency.

Environmental sustainability: The waste heat pump technology achieves effective utilization of waste heat, reduces waste heat emissions, and reduces environmental pollution. This environmental characteristic aligns with the pursuit of sustainable development in today's society.

Multi domain application: The exhaust heat pump can not only be applied in coal mine ventilation systems, but also widely used in other industrial fields. Its flexibility and versatility make it a multi-disciplinary green energy solution.

With the increasing demand for energy, the exhaust heat pump technology is expected to be promoted and applied in more fields. In the future, it can be foreseen that it will continue to make progress in technological innovation and performance improvement, making greater contributions to promoting green development in coal mines and other industrial fields.

The utilization of waste heat from coal mine ventilation shafts and exhaust heat pumps, as an innovative technology, have brought new possibilities for the rational utilization of energy in mining areas. By recovering and converting waste heat from exhaust air, we can not only improve energy utilization efficiency, but also achieve environmental and sustainable energy utilization goals. Under the guidance of green energy, exhaust heat pumps will undoubtedly become one of the highlights of energy management in the future mining and industrial fields.

Comment