The direct exhaust heat exchanger is an efficient and energy-saving heat exchange equipment, and its design principles and performance analysis are of great significance for promoting industrial production and energy utilization. This article will delve into the principles, characteristics, and advantages of direct exhaust heat exchangers in energy conservation and environmental protection, hoping to provide readers with a comprehensive and detailed understanding.

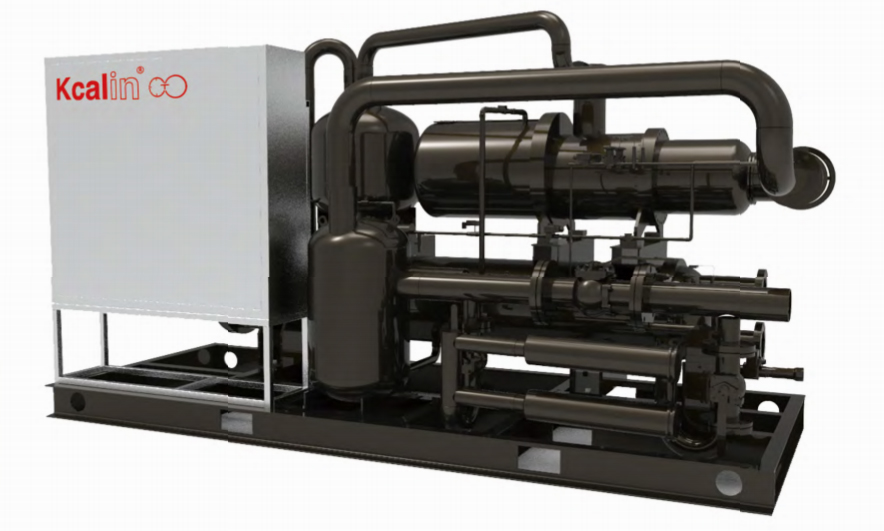

Working principle: The direct exhaust heat exchanger directly exchanges heat between two media (usually gas and liquid) inside the heat exchanger. Among them, exhaust air refers to gas containing less heat, while the heat exchanged air has a higher temperature. The direct exhaust heat exchanger utilizes sealed pipes and finned radiators to quickly transfer heat between exhaust and hot air internally, achieving efficient heat exchange.

Design points: The design points of a direct exhaust heat exchanger are to optimize the heat exchange area, increase the contact time between hot air and exhaust air, and reasonably layout the heat transfer structure inside the heat exchanger. Designers usually consider factors such as the speed of fluid flow, the selection of heat exchanger materials, and the structural design of the heat exchanger to ensure that the heat exchanger can operate efficiently while balancing stability and durability.

performance analysis

Efficient heat exchange: The direct exhaust heat exchanger adopts a direct heat exchange method, eliminating the conduction, heat transfer, and mass transfer resistance in traditional heat exchangers, greatly improving heat exchange efficiency. The contact area between the exhaust air and the hot air inside the heat exchanger is large, and the heat transfer is fast, resulting in a rapid increase in the temperature of the exhaust air and a decrease in the temperature of the hot air, achieving efficient energy conversion.

Energy conservation and environmental protection: The direct exhaust heat exchanger can effectively recover the heat energy from the hot air and transfer it to the exhaust air, thereby reducing the energy consumption of the exhaust air and achieving energy conservation. Compared with traditional heat exchange equipment, direct exhaust heat exchangers have higher energy utilization efficiency, which can reduce greenhouse gas emissions such as carbon dioxide, protect the environment, and have environmental benefits.

Flexible application: The design structure of the direct exhaust heat exchanger is relatively simple, compact, and easy to install and maintain. In addition, it is suitable for various industrial fields, such as petrochemical, power, metallurgy, papermaking, etc., and can meet the heat exchange needs of different fields and processes.

Increase production capacity: In some industrial production processes, a large amount of hot air is required for heating or drying. The direct exhaust heat exchanger can recover and utilize the heat energy in the exhaust air, increase the temperature of the hot air, thereby increasing production capacity, reducing energy consumption and production costs, and has a positive effect on improving the economic benefits of enterprises.

Safe and reliable: The direct exhaust heat exchanger adopts a sealed design, ensuring the exchange of exhaust air and hot air inside the heat exchanger, avoiding cross contamination with the external environment, and ensuring the safety of the production process. Meanwhile, high-quality materials and stable structural design ensure the reliability and durability of the heat exchanger.

The design principle and performance analysis of the direct exhaust heat exchanger, as an efficient and energy-saving heat exchange equipment, demonstrate its important role in promoting industrial production and energy utilization. Through an efficient heat exchange process, the direct exhaust heat exchanger can effectively recover heat energy, achieve energy conservation and environmental protection. Its flexible application and reliability provide sustainable support for industrial production and play an important role in increasing production capacity and reducing production costs. I believe that with the continuous innovation of technology and the promotion of application, the through type exhaust air heat exchanger will undoubtedly exhibit broader development prospects in various fields.

Comment