As an important energy and resource extraction base, the heating and wellhead antifreeze work of mines are crucial for ensuring production and employee safety. This plan proposes a comprehensive utilization plan that integrates mine heating and wellhead freezing prevention, utilizing the waste heat resources of mine exhaust air for heating and solving the problem of wellhead freezing. This scheme achieves efficient energy utilization and intelligent management of the system through technical means such as heat energy recovery and conversion, heat energy storage and transmission, and intelligent control. This plan can not only reduce energy consumption and environmental pollution in mines, but also improve heating quality and wellhead antifreeze effect, with great application potential and economic benefits.

1、 Background and significance

As an important source of energy and resources, mines' heating and wellhead antifreeze work are crucial for ensuring production and employee safety. The traditional heating methods in mines usually use coal-fired boilers or electric heaters, which have problems such as energy waste and environmental pollution; However, wellhead antifreeze mainly relies on equipment such as electric heating rods, which consumes a lot of power and has limited effectiveness. Therefore, developing a heating and wellhead antifreeze solution that can comprehensively utilize mining resources and improve energy efficiency is of great practical significance.

2、 Plan content

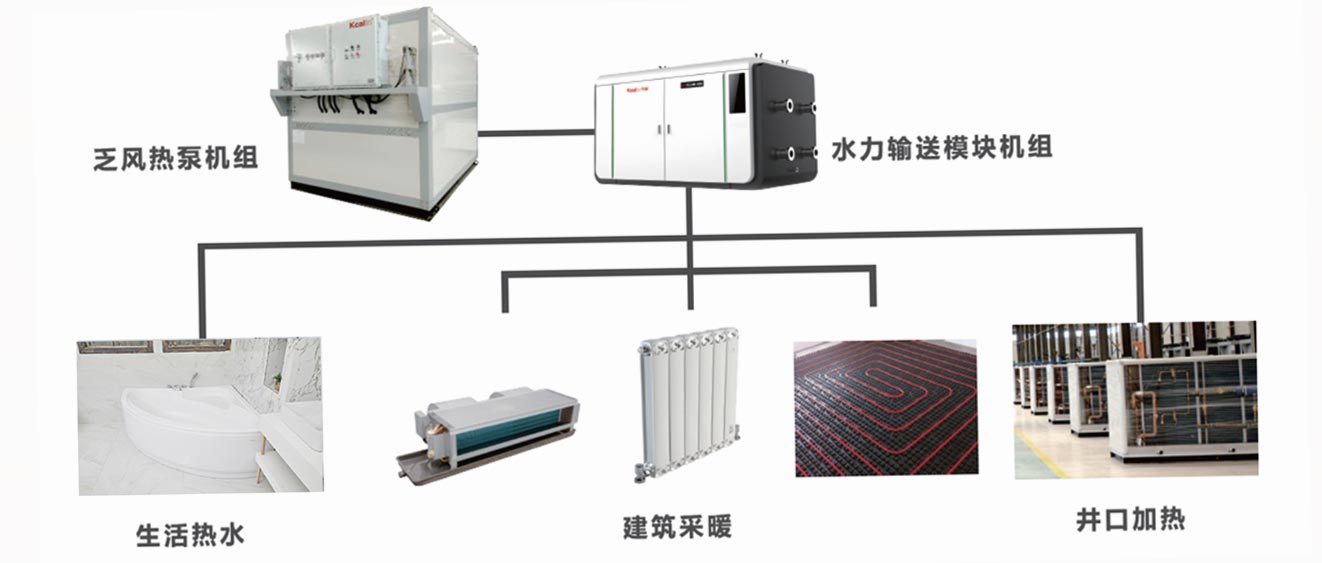

Heat energy recovery and conversion: The key content of this plan is to use the waste heat resources of mine exhaust air for heating. By installing a heat exchanger, the waste heat of exhaust air is converted into hot water or steam, which is supplied to the heating system in the mine. The recovery and conversion of waste heat from exhaust air can not only effectively reduce energy waste, but also lower the temperature and humidity of the mine and improve the working environment of miners.

Thermal energy storage and transmission: In order to meet the needs of the heating system, it is necessary to build a thermal energy storage and transmission system. Heat storage tanks or underground heat storage layers can be used to store waste heat from exhaust air, and heat energy can be transmitted to various heating areas through hot water pipelines or steam pipelines. The thermal energy storage and transmission system needs to consider factors such as the selection of thermal storage media, pipeline layout, and insulation to ensure efficient transmission and supply stability of thermal energy.

Intelligent control system: In order to achieve intelligent management of heating and wellhead antifreeze systems, monitoring and control technology can be introduced. Real time monitoring of temperature, humidity, heating load and other parameters inside the mine through sensors, and intelligent regulation based on monitoring data. The control system can automatically adjust the supply temperature and flow rate of hot water or steam, allocate energy according to actual needs, and improve energy utilization efficiency and heating effect.

Wellhead antifreeze technology: To address the issue of wellhead antifreeze, equipment such as heating rods and belts can be used for heating and insulation. Monitor and control the temperature of the wellhead through an intelligent control system, adjust the working status of the heating equipment in a timely manner, maintain the temperature of the wellhead within a safe range, and prevent the occurrence of freezing accidents.

3、 Advantages of the plan

Comprehensive utilization of resources: By utilizing the waste heat resources of mine exhaust air, efficient energy utilization and reduced energy waste have been achieved.

Environmentally friendly: Compared to traditional coal-fired boiler heating methods, the comprehensive utilization scheme of exhaust air and waste heat can reduce the emissions of carbon dioxide and other pollutants, with less impact on the environment.

Improving heating quality: The heating method of exhaust air and waste heat can provide a stable heat source, improve the temperature and humidity environment inside the mine, and improve the work comfort and production efficiency of miners.

Enhance the anti freezing effect of the wellhead: By monitoring and regulating the temperature of the wellhead through an intelligent control system, it can timely prevent the occurrence of wellhead freezing accidents and ensure the safe operation of the wellhead.

4、 Summary

The integrated utilization plan of mine heating and wellhead antifreeze for waste air and waste heat has achieved efficient energy utilization and intelligent management of the system through technical means such as heat energy recovery and conversion, heat energy storage and transmission, and intelligent control. This plan not only reduces energy consumption and environmental pollution, but also improves heating quality and wellhead antifreeze effect, and has broad application potential and economic benefits.

Comment